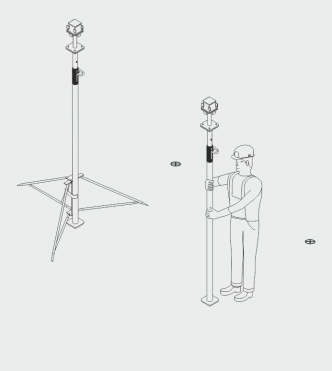

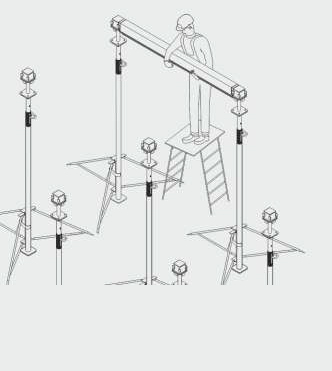

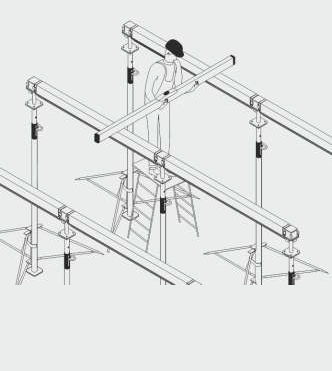

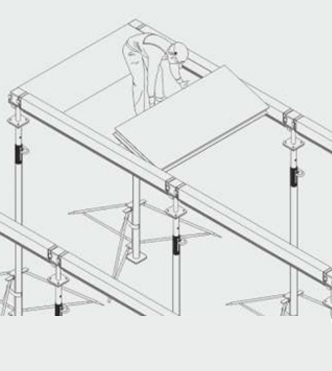

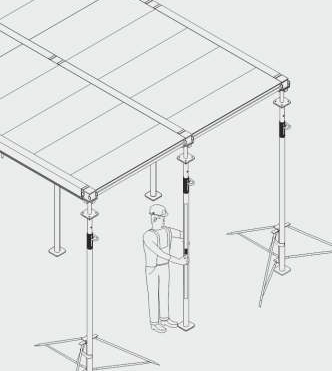

Max Deck is hand – set panelised slab Formwork system that offers three methods of Forming system –covering virtually any slab job in one and same system. Using the same parts avoids assembly error. The number of Props defined by the system ensuring safety and quick assembly.

We believe that our expertise will speed up your process and resolve your worries.

Ask the ExpertWe believe that our expertise will speed up your process and resolve your worries.

Ask the ExpertOur designs can be verified by any of the reputed institute such as IIT or structural consultants.

• The all components of MaxDeckhas been designed according to the guidelines given in ACI 347 and BS 5957.